Scatteres polymer asphalt

The Blend Preparation of Asphalt / Polymer

Large volumes of polymer-bitumen blends are used in roofing, road surfacing and waterproofing applications, and the mixing process employed can have a significant effect on both the technical properties of the resulting blend and the economies of the whole operation. A number of factors influence the mixing process and it is th object of this bulletin to describe these factors and their significance and to outline how the operation may be optimised.

The parameters influencing the mixing process may be defined as follows:

* Nature (grade) of polymer

* Physical form of polymer

* Nature and grade of bitumen

* Type of equipment

* Time-temperature profile during mixing

The last of these is not strictly an independent variable, but its importance in the context of subsequent performance of the blend warrants its inclusion here

Inline High Shear Mixers

For the continuous processing or batch recycling of products, we have a complete range of high shear inline mixers from the 0.25 kW laboratory unit to the 125 kW Multishear Mill. Designed to exacting standards, their construction makes it physically impossible for any materials liquid or solid to bypass the precisio rotor/stator workhead. The machine’s own high volume centrifugal action – from 10 Iitres/minute up m 250,000 litre/hour – will in most cases satisfy the user’s requirements without the need for auxiliary pumps

model registered ©

Equipo de Laboratorio para Dispersión de Polímeros y Ralladuras de Neumáticos Volumen: 0,5litros

Dispersor de Laboratorio semi-automático

NATURE (GRADE) OF POLYMER

For a given set of mixing conditions on a given plant, the time required to achieve a homogenous blend of polymer and bitumen will vary with the molecular weight build-up of the polymer, which is reflected to some extent in the final viscosity of the polymer. Higher molecular weight (or viscosity) will give rise to longer blending times, and vice versa.

PHYSICAL FORM OF POLYMER

The physical form of the polymer influences the blending process in two ways. The smaller the particle size of the polymer, the less reduction is required in any disintegration step in the process. In addition, since smaller particle size means larger surface area per unit mass of polymer, penetration of the bitumen and swelling of the polymer is facilitated and thus more rapid solution is achieved. Powdered polymer grades will therefore disperse and dissolve more rapidly than porous pellets. Indeed, it may be possible to blend powdered polymer with bitumen employing only low shear equipment and without any disintegration stage. Whether this is cost effective depends on the equipment available; if this is already high shear, then the extra cost of powdered polymer may not be justified.

NATURE AND GRADE OF THE BITUMEN

The bitumen plays a rather complex role in the mixing process since both its composition and its viscosity affect th blending in more than one way. Bitumens of higher maltenes content or higher aromatics swell the polymer more rapidly than do those of higher asphaltenes content. Whether this is an advantage depends on the equipment used, e.g. excessive initial swelling will reduce the milling effect on the polymer when passed through high shear mixers. Thus in this equipment the shortest premix time compatible with initial dispersion of the polymer in the bitumen should be employed. However, if a powdered grade of polymer is being used, with low shear mixing, rapid swelling will be beneficial. Low viscosity in a bitumen is helpful in increasing speed of penetration and swelling of the polymer particles. If the viscosity at blending temperatures is low, the disintegration effect on passing through th milling step will be improved and more rapid particle size reduction will result. Initial pre-dispersion will also be aided by low viscosity of the bitumen. It is unlikely that the selection of a bitumen will ever be made solely on the basis of its viscosity-temperature curve or its speed of penetration into the polymer; the performance aspects of the finished blend are likely to be the dominant factors in the choice of bitumen, and the mixing process will generally be tailored to the formulation.

Mini Lab equipment used for 0,5 liter capacity

multi-purpose laboratory mixers offer proven and unsurpassed efficiency in day to day laboratory work. Engineered with the same care and attention characteristic of the larger machines, they offer outstanding reliability and are perfectly suited to small scale production work. They also provide an accurate and easy means of forecasting the performance of larger machines under full scale working conditions.

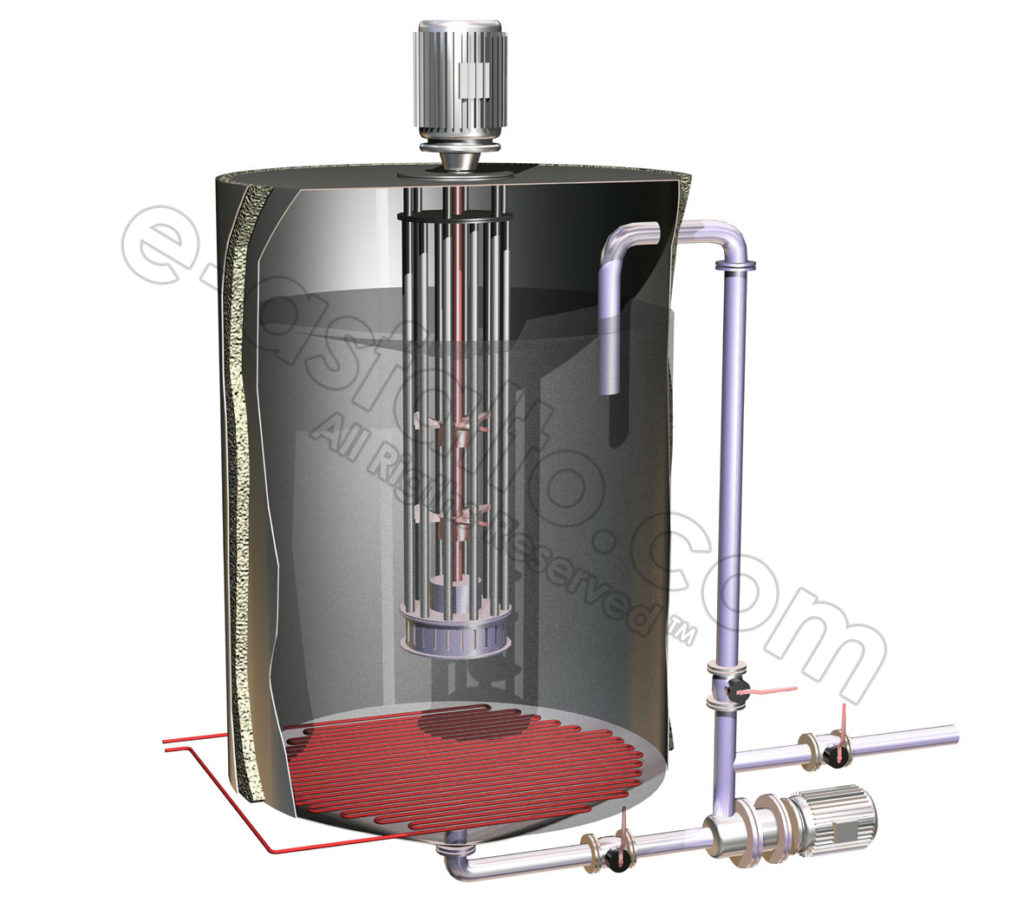

TYPE OF EQUIPMENT

Although there is a wide variety of mixers and dispersers on the market, these can in broad terms be divided into low shear and high shear appliances. In the former, typically paddle or propeller type, no particle size reduction of the polymer takes place, the action being confined to the swelling and dissolving by the bitumen. The mixer serves to maintain homogeneity of composition and uniformity of temperature, providing little heat input itself. In the latter there is a stage in which the polymer particles are physically reduced in size by mechanical/hydrodynamic shear in a rotor-stator combination accompanied by a significant input of heat energy to the mix. Such equipment, whilst functioning as a grinding stage, also provides rapid and efficient dispersion and mixing of the plymer in the bitumen. High shear equipment exists in two forms-the immersion type and the passthrough type. In the former, as the name implies, the rotor-stator combination is mounted on a shaft and immersed in a tank of material, depending on the efficiency of the mixing head to circulate material and achieve homogeneity. In the latter the material is positively passed through the milling equipment mounted in-line between two vessels either by an auxiliary pump or by the action of the mill itself in combination with the head due to gravity depending on the plant layout. Experience has shown that this type of equipment, which ensures that all of the mix passes through the rotor-stator gap, gives much more rapid disintegration-and thus solution-of the polymer than does the immersion type.

TIME-TEMPERATURE PROFILE DURING MIXING

The ideal mixing process would involve the lowest possible temperature for the shortest possible time (compatible with complete incorporation of the polymer into the bitumen) both from the point of view of economics and to minimise any changes in bitumen or polymer resulting from thermal effects. Whilst the time cycle is a function of the efficiency of mixing and solution, the temperature will to a large extent be a function of the bitumen chosen and its requirements to achieve mobility and initial swelling of the polymer. However, empirically, it has been found that for penetration bitumens used in combination with polymer an operating temperature range of 170-190°C is generally satisfactory. Temperatures above this must be avoided for reasons which are discussed later.

TYPE OF EQUIPMENT

Although there is a wide variety of mixers and dispersers on the market, these can in broad terms be divided into low shear and high shear appliances. In the former, typically paddle or propeller type, no particle size reduction of the polymer takes place, the action being confined to the swelling and dissolving by the bitumen. The mixer serves to maintain homogeneity of composition and uniformity of temperature, providing little heat input itself. In the latter there is a stage in which the polymer particles are physically reduced in size by mechanical/hydrodynamic shear in a rotor-stator combination accompanied by a significant input of heat energy to the mix. Such equipment, whilst functioning as a grinding stage, also provides rapid and efficient dispersion and mixing of the plymer in the bitumen. High shear equipment exists in two forms-the immersion type and the passthrough type. In the former, as the name implies, the rotor-stator combination is mounted on a shaft and immersed in a tank of material, depending on the efficiency of the mixing head to circulate material and achieve homogeneity.

In the latter the material is positively passed through the milling equipment mounted in-line between two vessels either by an auxiliary pump or by the action of the mill itself in combination with the head due to gravity depending on the plant layout. Experience has shown that this type of equipment, which ensures that all of the mix passes through the rotor-stator gap, gives much more rapid disintegration-and thus solution-of the polymer than does the immersion type.

STABILITY OF BLENDS

All polymer maintained at elevated temperatures for long periods will be subject to three competing reactions: increase in molecular weight, perhaps even leading to gelation, caused by cross linking of the unsaturated bonds; a similar, oxygen induced, polymerisation; and breakdown reactions. Additionally bitumens are subject to hardening on prolonged high temperature exposure. All of these reactions can be minimised by maintaining close control of operating temperatures and residence times in the mixing equipment. Additional measures that will reduce any tendency to polymerise include antioxidants, a relatively expensive route, or nitrogen blanketing of the mixing vessel, which is very effective.

Basic Plant Construction And Layout

A bitumen/polymer production plant is essentially a simple construction designed to efficiently mix and dissolve bitumen, residual aromatic extracts and polymers to form bituminous compounds suitable for use as binders in asphalt mixes, joint sealants, adhesives, roofing felt coatings, etc.

A plant normally comprises three stages:

- Raw materials storage and handling

- Mixing and dissolving

- Product storage and loading

A typical plant will comprise the following:

- Two raw materials bulk storage tanks

- Polymer storage and handling area. one or two mixing vessels

- High shear disintegrator/mixer

- Product storage tanks

- Packing/loading facility

- Boiler room (hot oil facility)

- Control room

In addition, there is a requirement for plant utilities such as electricity, water, compressed air, hot oil heating, etc., and for facilities such as a laboratory and offices. The ground area required for a plant will depend upon the maximum throughput of the plant.