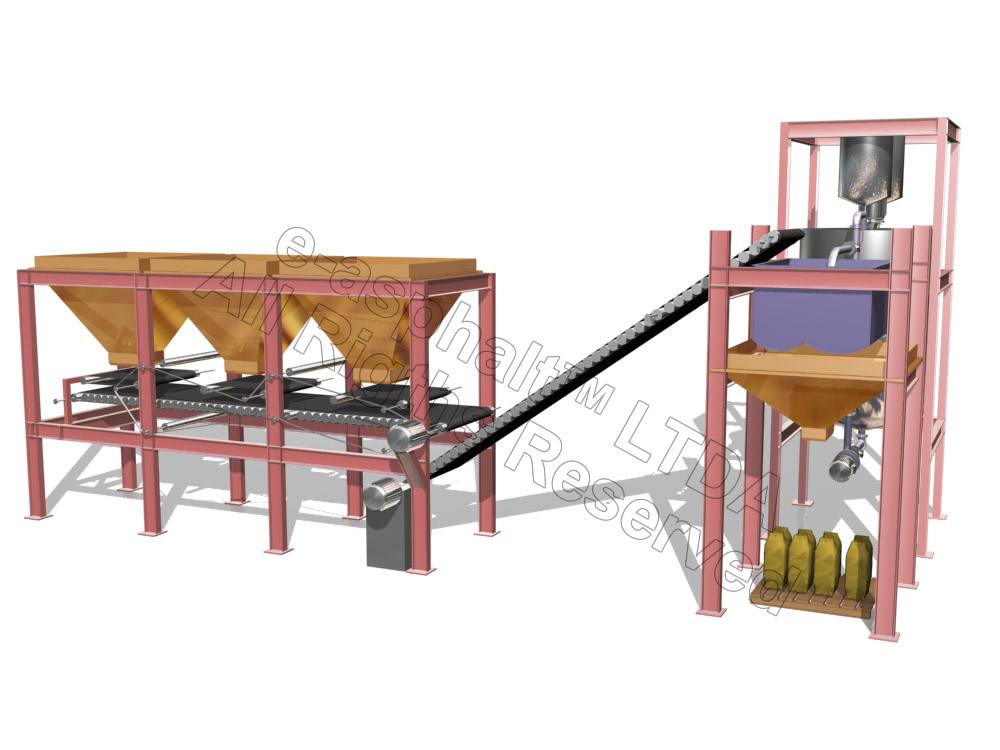

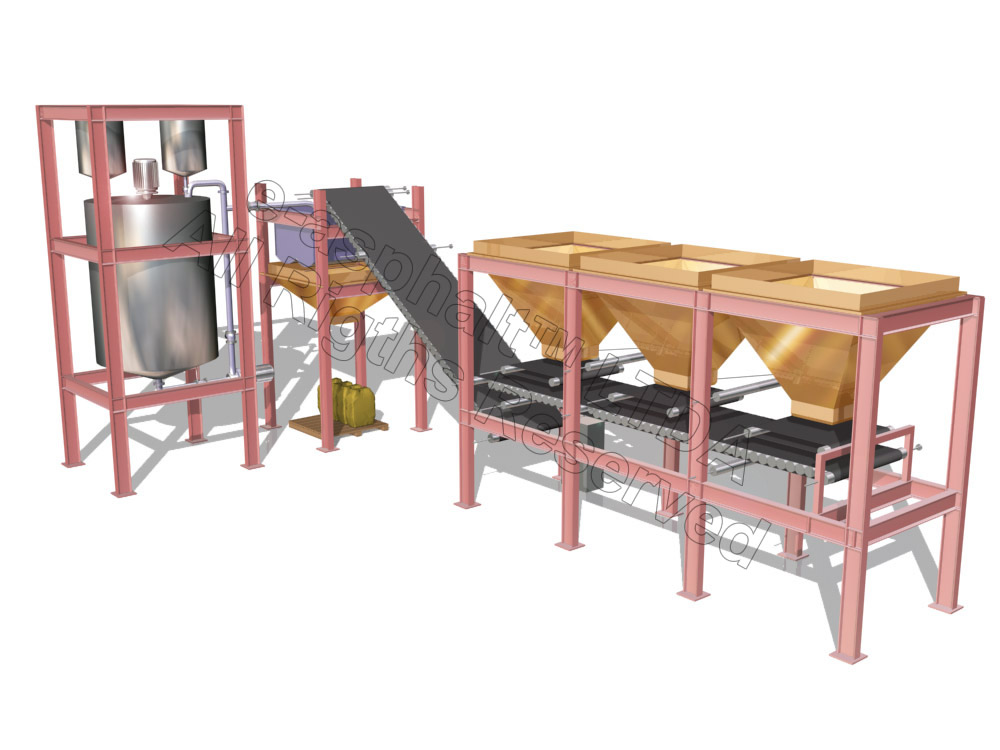

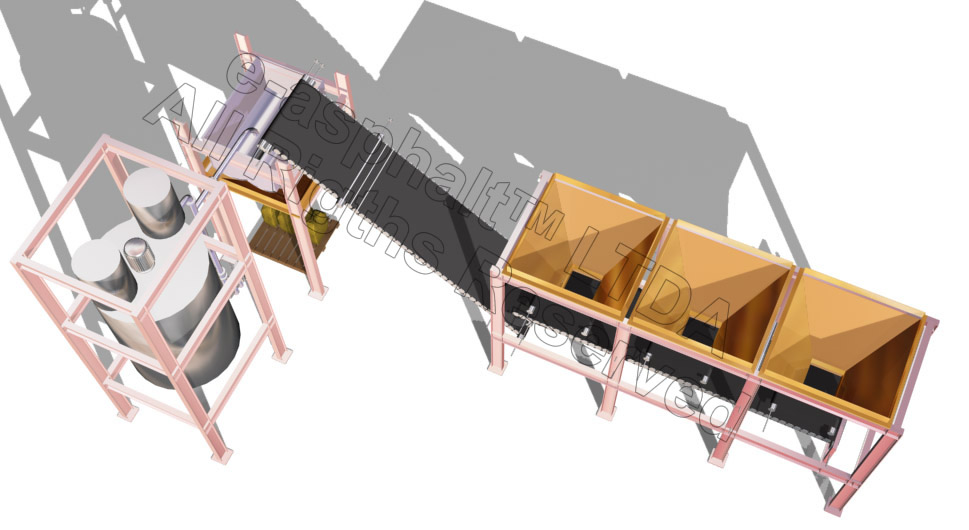

Cutback cold mix asphalt plant

Cold-mix asphalt is not a sophisticated preparation. Generally, placing and compacting do not normally call

for equipment as sophisticated as that required for hot-mix asphalt. This type of pavement construction, however, is

no less important since a large percentage of the nation’s roadways have cold-mix asphalt bases and even surfaces.

Less control is required for cold-mix preparation with a distributor and motor-grader operation. But possibilities

for as great a control as for hot-mix asphait are present

in a plant-mix operation.

However, many plants used for producing cold mixes do not use or have all the meansfor maintaining close uniformity of control. Wherever suitable materials are available, such plant mixing procedures are employed for high production and low cost.Cold-mix recycling or reworking of existing asphalt pavement or aggregate structures is another important pavement construction alternative.

Cold-mix recycling is the process in which reclaimed asphalt material, reclaimed aggregate materials or both are combined with new asphalt in place or at a central mixing facility to produce cold-mix base mixtures.

Cold-Mix AsphaIt Pavements

Introduction

Description

Cold placed asphalt pavement mixtures (or simply cold mixes) are generally mixes made with emulsified or cutback asphalt. Emulsified asphalts may be anionic or cationic MS and SS grades. Cutback asphalts may be MC or SC grades.

Aggregate material may be anything from a dense-graded crushed aggregate to a granular soil having a relatively high percentage of dust. The aggregate at the time of mixing may be either damp, air-dry, or artifícially heated and dried.

Mixing methods may be performed either in the roadway, along the roadway, or in a stationary mixing facility.

The resulting mixtures usually are spread and compacted at atmospheric temperature, however, there are exceptions. Some asphalt mixes made with MC- and SC-3000 are similar to hot asphalt mixes because they are mixed and placed at temperatures in excess of 93°C (200° F). Also, some emulsión mixtures might be produced either warm or hot.

Suitability for Pavement Construction

Cold-laid asphalt mixes may be used for surface, base, or subbase courses ifthe pavement structure is properly designed. Cold-laid surface courses are suitable for light and medium traffic. When used in the base or subbase, they may be suitable for all types of traffic. Cold-laid pavements have special advantages in outlying areas where economic problems exist in getting the necessary improved mileage. Also used on large jobs, cold-laid paving mixtures reduce construction costs, but not necessarily the strength or

quality of the pavement structure. Asphalt pavements made by cold-laid methods can be designed and built to meet current traffic requirements. They can also be increased in thickness, as may be dictated for subsequent traffic, by adding additional pavement courses.

Mix Composition

A wide variety of aggregates and soil-aggregate combinations can be processed. There are many cases where material from road cuts, pits, or nearby quarry sites may be economically crushed or used. Often the entire output below a certain maximum size from a rock crusher is used. Suitable local materials also include granular soils having up to 20 percent passing the 75 um (No. 200) sieve, as well as clean sands and gravels. Granular materials that are mostly fine aggregate and have relatively high percentage mineral dust may cause mixing, aeration, and compaction problems. Well-graded aggregates are always desirable for any course of the asphalt pavement structure, but many poorly graded and gap-graded aggregates are adequate for base courses when properly prepared by road mixing methods and procedures.

Asphalt

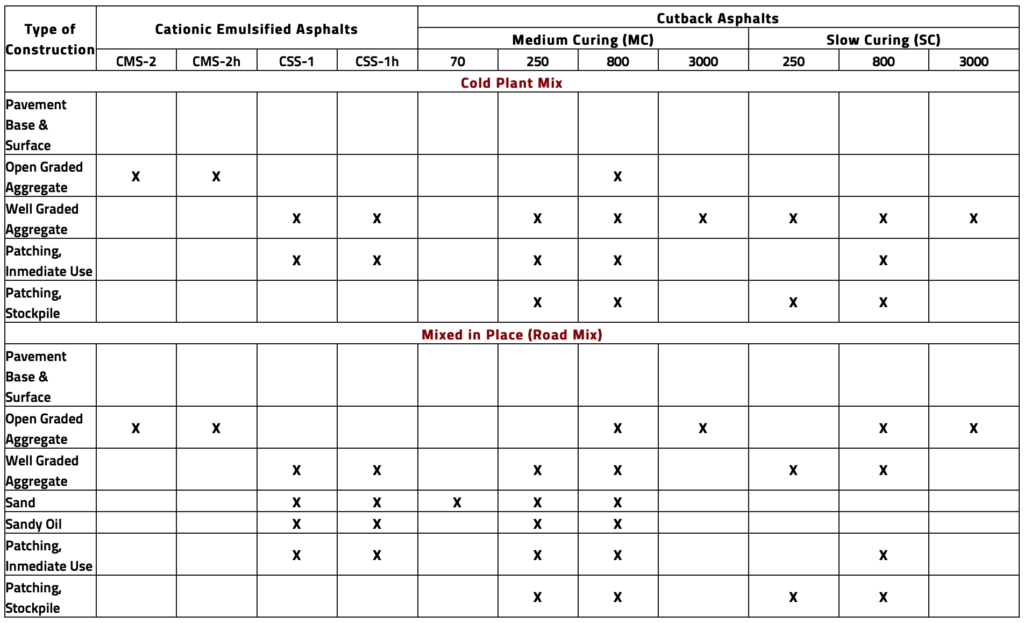

The type and grade of asphalt selected for use in cold-laid pavement construction depends a great deal upon the aggregate, mixing method, and climatic conditions. Recommended asphalts for different types of cold-laid pavement mixtures are given in Table.

Mixtures prepared at a stationary mixing facility generally permit a more viscous grade of asphalt than used in the road-mixing method. Cool weather conditions require a lower viscosity grade and permit a faster curing or setting type of asphait to be selected than for warmer or hot weather mixing conditions. Mixtures prepared with emulsifíed asphalt do not require aggregates as dry as those prepared with cutback asphalts

This reduces the amount of manipulation or extent of air-drying prior to mixing the aggregate with asphalt. Cold-laid asphalt mixtures prepared for maintenance use and stockpiled over a period oftime usually are prepared by using one of the lower viscosity grades of the MC or SC cutback asphalts.

Proportioning the Materials

The amount of asphalt for cold-laid paving mixtures may be determined by one of the following laboratory procedures:

1. Methods of Test for Resistance to Deformation and Cohesion of Bituminous Mixtures by Means of Hveem Apparatus,

ASTM D 1560

2. Centrifuge Kerosene Equivalent (CKE) method

Where laboratory equipment is not available, formulas may be used for approximating the asphalt content for initial mixing.

For estimating the approximate emulsified asphalt content in dense-graded mixes the following empirical formula may be used:

P = (0.05A + 0.1B + 0.5C) x (0.7)

where:

P = percent of total emulsified asphalt by weight of dry aggregate,

A = percent of aggregate retained on the 2.36 mm (No. 8) sieve,

B = percent of aggregate passing 2.36 mm (No. 8) and retained on 75 um (No. 200) and

C = percent of aggregate passing 75 um (No. 200).

(All above percentages should be expressed as whole numbers.)

Guide for Uses of Asphalt in Cold Mix