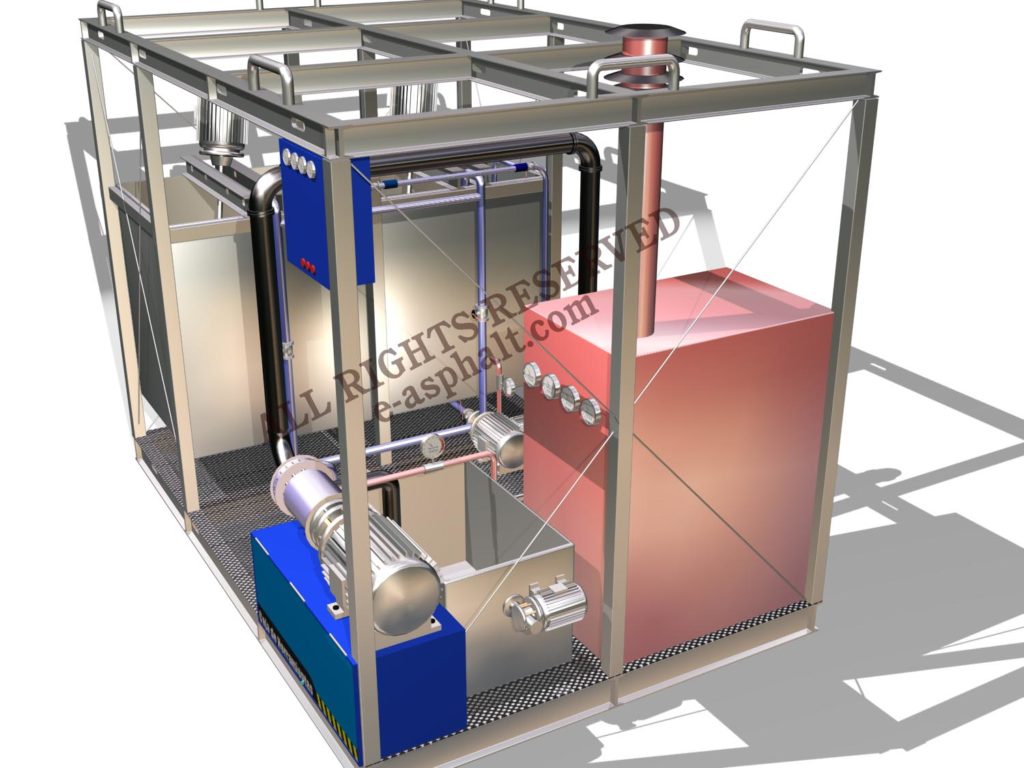

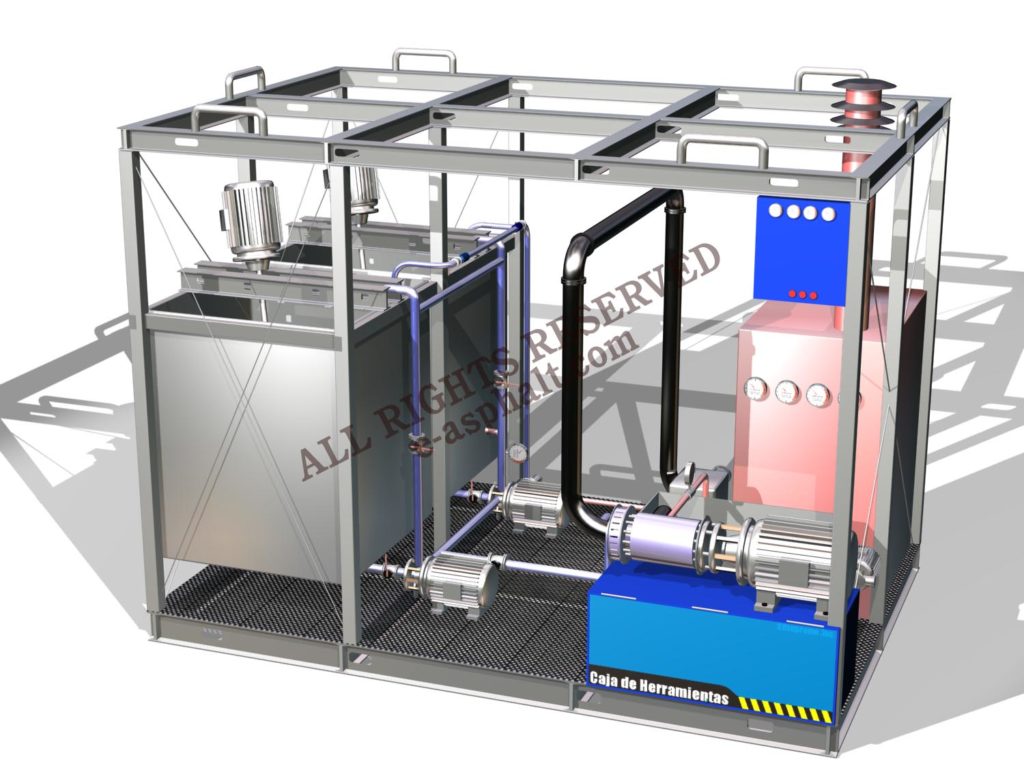

Asphalt emulsion portatile plant

Solga 50/2 Plant, capacity 5/10 m3/hour, with storage tank for emulsion, approx. 5 m3 capacity,

placed on the top of the plant.

The Solga Plant permit to:

- Fully automatic operation

- Alter with great facility the ratio in percentage between water and bitumen

- Produce acid or basic emulsion

- Control product quality on sample before starting final production

- Save menpower

- Electrical panel with all the controls and start.

- Thermostatic valve to maintain automatically the emulsion temperature in the storage tank.

- Two counterweight indicate the bitumen and water quantity in the basin.

- Mill and pump with valves to fill with emulsion the storage tank and to agitate the product.

- The bitumen pump heated with oleotermic oil: the water pump self lubrificated.

- All drives are automatically controlled

- Geared volumetric pump, placed at the base of the plant, will allow to store the emulsion onto charge directly the lorry tankers.

- In the rear part of the plant there is the place to put in the additives for the emulsion and to control their agitation.

The production range does includes in addittion:

- Asphalt storage and heating plant

- Steam producers with diatermic oils

- Diatermic oil heaters

- Asphalt spreading and transport tanks

- Welters for bitume in drums or blocks

- Equipment for road maintenance

- Burning oil heaters and heat exchangers

- Plants for bitume fluidification serial MC1/ MCO

- Asphalt and resins mixers

- Central heating groups to heat up machines in the field of paper and boards with bitume backing

- Fabric bag filters

- High performance sludge dehydrator

- Conglomerate plants