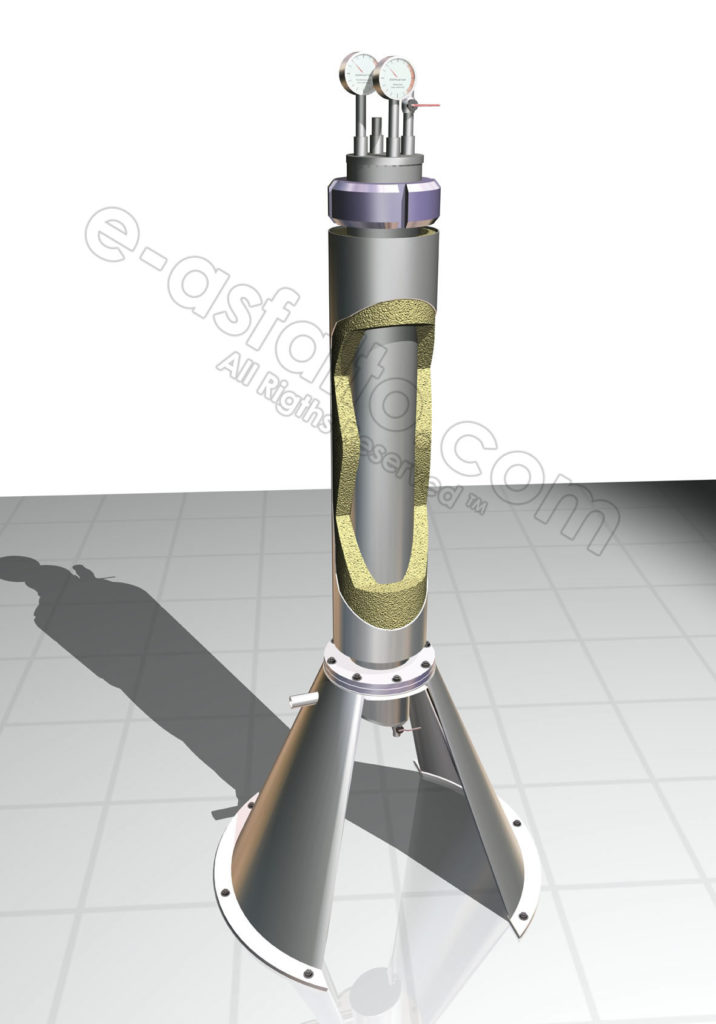

Asphalt blown pilots units

Introduction

Special properties may be imported to asphalt by blowing air through the topped crude fraction during the latter part of the refining process. The regular distillation process is discontinued at some point while the topped crude is still liquid. The heavy fraction is then put into a converter and air is blown through it while it is maintained at a high temperature. This process is continued until the asphalt has attained desired properties. Often, such asphalts are called oxidized asphalts. However, this is not strictly a true term because not only oxidation but also vaporization, dehydrogenation, condensation, polymerization and other reactions occur during the airblowing process.

One of the most significant properties of air-blown asphalt is that the temperature at which asphalt becomes soft is raised. This temperature is usually called the softening point of asphalt. Even at this temperature asphalt still retains its waterproofness and durability. However, there is some reduction in -ductility as compared with asphalt cement for paving purposes.

Blown asphalts are used for a wide variety of industrial and specialty purposes. Just a few of these are: a variety of roofing applications, pipecoating enamels, undersealing asphalts to sill cavities beneath portland cement concrete pavements, and waterproof membranes for lining canals and reservoirs. In many instances blown asphalts are applied in pure form. In other cases, very fine mineral powders (fillers) are mixed with blown asphalt prior to application. Only rarely, if ever, are blown asphalts used in asphalt-aggregate mixtures for paving purposes.

Properties and Specifications

Although similar in many respects to the normal paving grades of asphalt cement previously discussed, the blowing process provides materials that soften at higher temperatures than asphalt cements. Because the higher softening point is a most important and desirable property of blown asphalts, they are usually classified in terms of the ring and ball softening point test, rather than viscosity or penetration.

While blown asphalts are graded on the basis of the softening point, there are still penetration test requirements at three temperatures 0°C, 25 °C, and 46°C (32 ° F, 77 ° F, and 115 ° F). These requirements provide a degree of control over the temperature susceptibility, or the rate of consistency change with temperature, for these materials.

Petroleum Asphalt

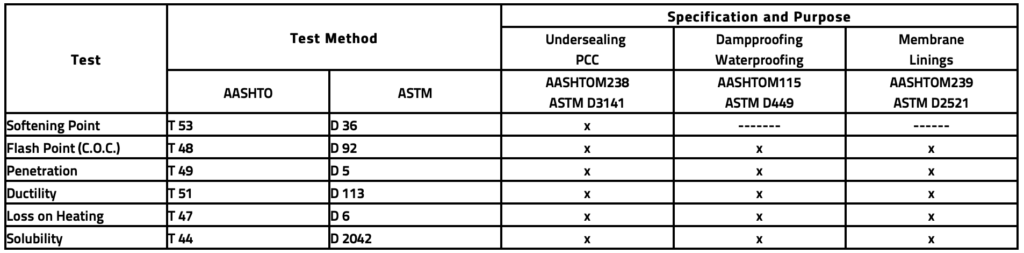

Specifications have been adopted by AASHTO and ASTM for specialized uses. Although blown asphalts are not normally specified by name, a blowing process is usually required to produce an asphalt that will meet specifcation requirements. Required tests for some specialized specifications are listed in Table along with the appropriate AASHTO or ASTM test method. These tests are briefly described in the following paragraphs.

Required Tests for Some Blown Asphalt Cements

Softening Point Test

The softening point test is used as the basic measurement of consistency for grading blown asphalts. Samples of asphalt loaded with steel balls are confined in brass rings suspended in a beaker of water, glycerine, or ethylene glycol at 25 mm (1 in.) above a metal plate. The liquid is then heated at a prescribed rate. As the asphalt softens, the balls and the asphalt gradually sink toward the plate. At the moment the asphalt touches the plate, the temperature of the water is determined, and this is designated as ring and ball (RB) softening point of asphalt.

Penetration Tests

The specifications indicate penetration tests be performed at:

0°C (32°F) with 200-g needle for 60 s

25°C (77°F) with 100-g needle for 5 s

46 °C (115°F) with 50-g needle for 5s